Revolutionizing the industry through specialty gas expertise

When it comes to industrial processes like welding, precision and safety are of crucial importance. One key factor that plays a significant role in achieving these goals is the use of specialty gases. These specialized gases offer numerous advantages that contribute to efficient operations, welding safety, and overall productivity.

In this article, we’ll explore the key benefits of incorporating specialty gases into industrial processes you should know about.

Enhanced Welding Performance

Industrial processes, particularly welding, require high accuracy and control. Specialty gases, such as those found in welding supplies, provide improved welding performance due to their composition and purity. These gases, often referred to as industrial gases, offer precise control over factors like arc stability, heat input, and penetration depth. As a result, welders can achieve superior weld quality, ensuring that the final product meets or exceeds industry standards.

Welding Safety and Occupational Health

Safety is paramount in any industrial setting, and welding is no exception. Specialty gases contribute significantly to welding safety by reducing the risks associated with the process.

Compressed gas cylinders, which store these gases, are designed with superior safety measures to prevent leaks, contamination, and mishandling. The use of specialty gases minimizes the presence of impurities that can lead to weld defects, ensuring a safer working environment for welders and reducing the need for costly rework.

Optimized Material Properties

Certain industrial processes require specific material properties to achieve desired outcomes. Specialty gases play a crucial role in modifying material properties during processes like heat treatment.

By carefully selecting the right combination of gases, manufacturers can alter the hardness, durability, and other characteristics of metals. This level of precision allows for producing materials that meet specific performance requirements, reducing waste and enhancing overall efficiency.

Environmental Considerations

In today’s world, environmental responsibility is a significant concern for industries, and specialty gases can contribute positively to environmental sustainability. Unlike conventional gases, which might release harmful byproducts during processes, specialty gases are often formulated to minimize emissions and waste.

This reduces the carbon footprint of industrial operations, aligning them with eco-friendly practices.

Cost-Effectiveness

Though specialty gases may seem like an added expense, their advantages often translate into long-term cost savings. The improved quality and precision achieved with these gases can reduce the need for rework, repairs, and material wastage.

Moreover, the enhanced efficiency and productivity resulting from the use of specialty gases lead to quicker project completion, ultimately saving both time and money.

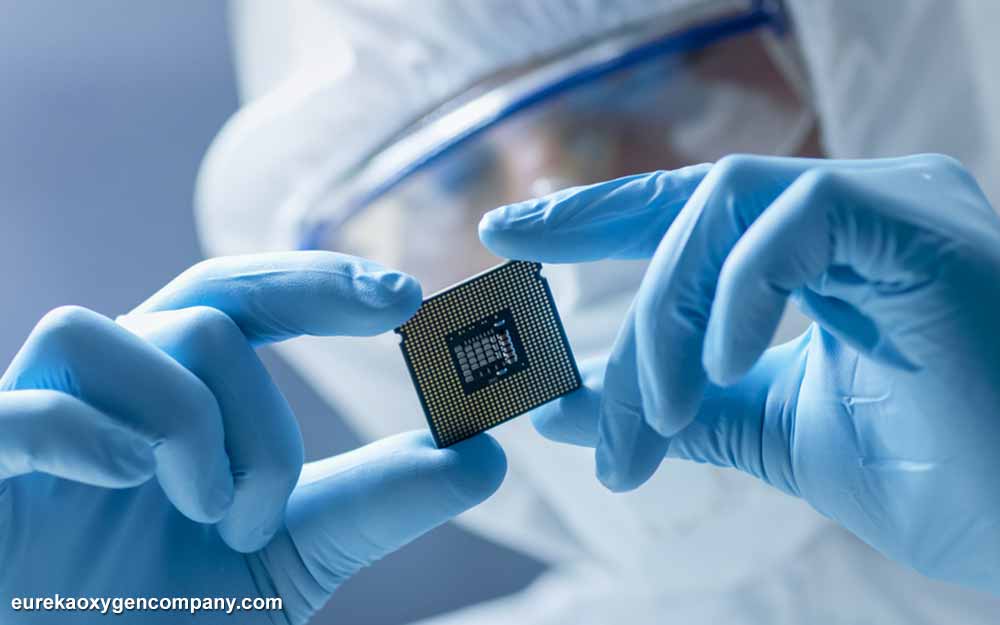

Wide Range of Applications

Specialty gases find applications beyond welding, thus they play a vital role in various industrial processes, including electronics manufacturing, pharmaceuticals, food and beverage, and medical applications.

In electronics manufacturing, these gases aid in the production of microchips and semiconductors. In the medical field, they are used for anesthesia and medical imaging equipment. The versatility of specialty gases underscores their importance across diverse industries.

Precise Calibration and Measurement

Industrial processes often require precise calibration and measurement to ensure accuracy in production, and specialty gases are the center of attention.

These gases are used as calibration standards for instruments that measure factors like pressure, flow, and temperature. By using gases with well-defined properties, manufacturers can calibrate their equipment to ensure reliable measurements, leading to consistent product quality and adherence to industry standards.

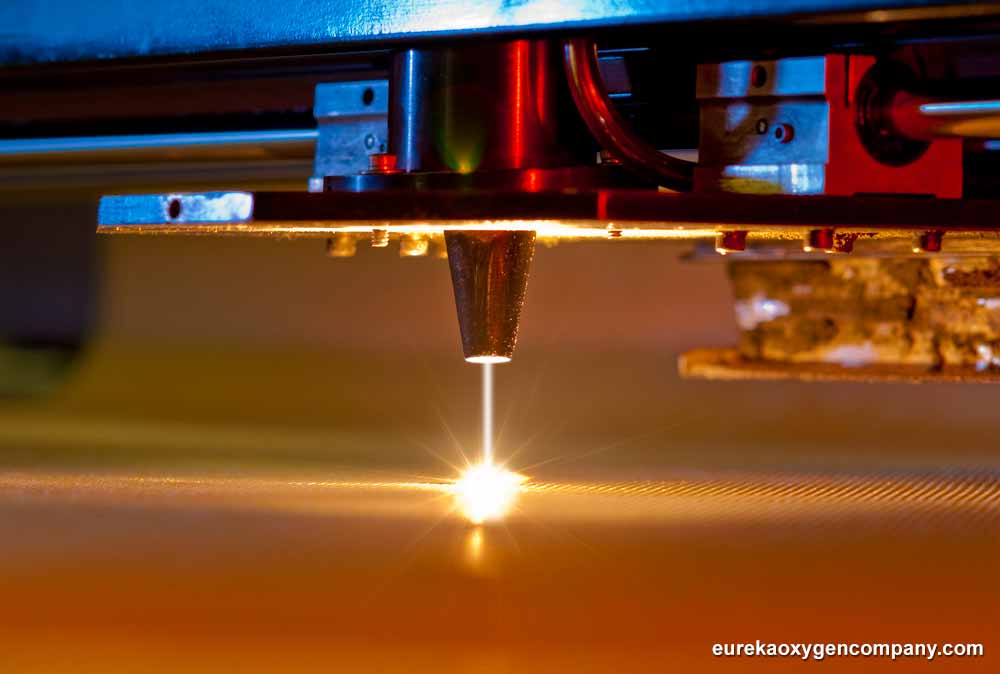

Reduced Heat Affected Zone (HAZ)

In processes like laser cutting and welding, heat can lead to a phenomenon known as the Heat Affected Zone (HAZ), where the surrounding material experiences changes in its properties due to elevated temperatures.

Specialty gases, particularly those formulated for laser applications, can help mitigate the size and impact of the HAZ.

By using gases that provide efficient cooling and control over the heat distribution, manufacturers can achieve precise cuts and welds without compromising the integrity of the surrounding material.

This results in minimal distortion, reduced need for post-processing, and enhanced overall product quality.

Conclusion

Incorporating specialty gases into industrial processes brings a multitude of benefits that cannot be ignored. From enhancing welding performance and safety to optimizing material properties and contributing to environmental sustainability, these gases play a crucial role in driving industrial efficiency and progress.

As technology continues to advance, the use of specialty gases will only become more integral to achieving higher standards of quality, safety, and productivity in various industries.

So, whether you’re working with compressed gas cylinders or utilizing welding supplies, remember that the advantages of specialty gases are there to support and elevate your industrial endeavors.

About Eureka Oxygen

For many years, Eureka Oxygen has been a trusted name in the field, offering a comprehensive range of specialty gases that cater to industries ranging from manufacturing and healthcare to electronics and beyond.

Our extensive portfolio covers everything from compressed gas cylinders to welding supplies, each designed to meet the unique needs of modern industrial practices. Take a look at the locations we serve and how we can help you, here.

We have a unique team of experts, armed with an in-depth understanding of gases’ intricate properties, to assist clients in harnessing the advantages of specialty gases.

Whether it’s enhancing welding performance, optimizing material properties, or ensuring compliance with stringent safety standards, Eureka Oxygen is here to help you achieve industrial success.